Observe the contractor or buyer with precautions when receiving the shipment at work. Each pipe shipment must be carefully inspected after reaching the project site.

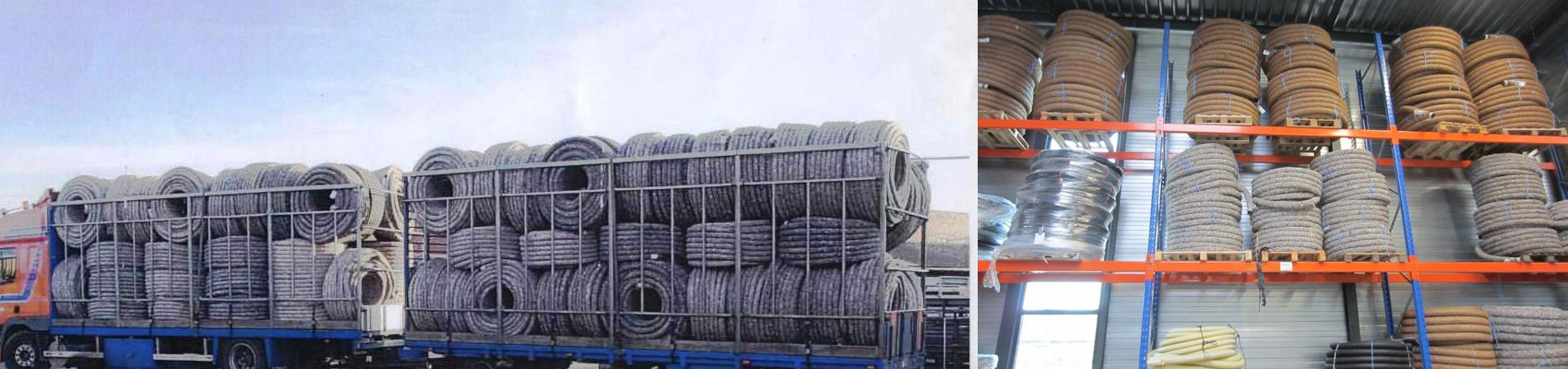

All shipments sent by Shahrab Gostar Water and Soil Company are loaded carefully and after the approval of the quality control unit, so after loading the product from the factory, the transport company is responsible for possible losses resulting from non-compliance with shipping conditions. The buyer or the contractor must inspect and receive the shipment at the time of delivery for any damage.

After receiving the goods, the buyer or contractor is responsible for maintaining and storing the goods, and for this purpose, the company submits instructions on how to properly unload, store and transport the pipes to the project site as follows.

Drainage pipe drainage instructions

2- Under no circumstances should the pipe (roll) be thrown down from the truck or pulled on the ground

3- Each roll (tube coil covered with synthetic fibers) by one worker inside the truck and 2 people at the bottom so that the person inside the container brings the coil to the end of the container and delivers it to two people at the end of the container. The two men take the spool (not from the threads tied around the spool) and gently place it in storage.

Warehousing conditions

2. Avoid storing more than three coils on top of each other.

3- In hot weather, the temperature of the hall should not exceed 50 degrees. For this purpose, keep the door and window of the warehouse hall open.

Send pipes to the workshop from the warehouse

2- The pipe should be carefully placed next to the trench or trench machine, etc.

3- The pipe should be completely controlled during the brokerage. If the fibers are damaged and the pipe is visible, the place exposed by the fibers and yarn, which is delivered to the workshop separately, should be repaired and reconstructed.

Note: How to repair and regenerate: Place some of the prepared fibers similar to the cover of the tube delivered to the user on the place of the fibers (the part without cover) and wrap it around with a thread.

The warehouse manager and the workshop manager, in coordination with the project managers, send only the required daily amount of covered pipe to the project site. Avoid storing the pipe at the project site for more than one week in spring and summer and two weeks in autumn and winter.

Instructions for loading, unloading, warehousing and maintenance of PVC-U double-walled Carogit pipes

2- In loading and unloading, pay attention that the pipe is moved slowly and avoid throwing the pipe

3- Storage conditions: When storing the pipe, make sure that no more than 6 rows of pipes are stacked on top of each other. The female shape of the pipe is that in case of pressure, the weight of the upper row of female pipes is likely to change its shape, which will cause problems in installing the pipe to each other.

4- PVC-U pipe is resistant to normal sunlight for 3 to 5 months and its slight discoloration does not mean destruction of material and quality of the pipe in case of need for long-term maintenance or practical use. Ground surface and in front of the sun, with the previous coordination and communication with Shahrab Gostar Water and Soil Company, the order of producing pipes resistant to direct sunlight can be done.